Potentiometer, Hall Effect, Inductive, Optical Joystick

Understanding the Progression of Joystick Technologies

Let us tell you a story of the “joystick”. Prior to being called a joystick it was known as a “control lever”, “handle” or just a “stick". It involved mechanical linkages between a person and a physical device (apparatus) that needed to move in one direction or the other. The problem soon became apparent that a person could only control that apparatus based upon their own physical limit of the amount of force that could be applied to the mechanical control lever. It wasn’t until the knowledge of adapting electrical circuitry (specifically the changes in voltages or current levels) that the idea of controlling physical devices (mechanical components) that required much more force than a person could possibly exert upon the handle or lever that the invention of the “joystick” became a reality. The person who needed to control a large or heavy object or even a very distant object could do so by applying a small amount of force to a “stick” and accomplish tasks with relative ease or “joy”, in doing so the term “joystick” was coined. It became so widespread, so quickly, that today it is known around the globe only as a “joystick”, there is no direct translation of this word into any other language.

One of the first applications of the “joystick” was in the field of aerospace, where the control of the ailerons and elevators became a necessity. This usage of electrical signals from the joystick to ultimately move a mechanical part of the plane in one direction or the other came to be known as “fly by wire”. There are literally thousands of applications today that take advantage of electronic signaling joystick to control motion.

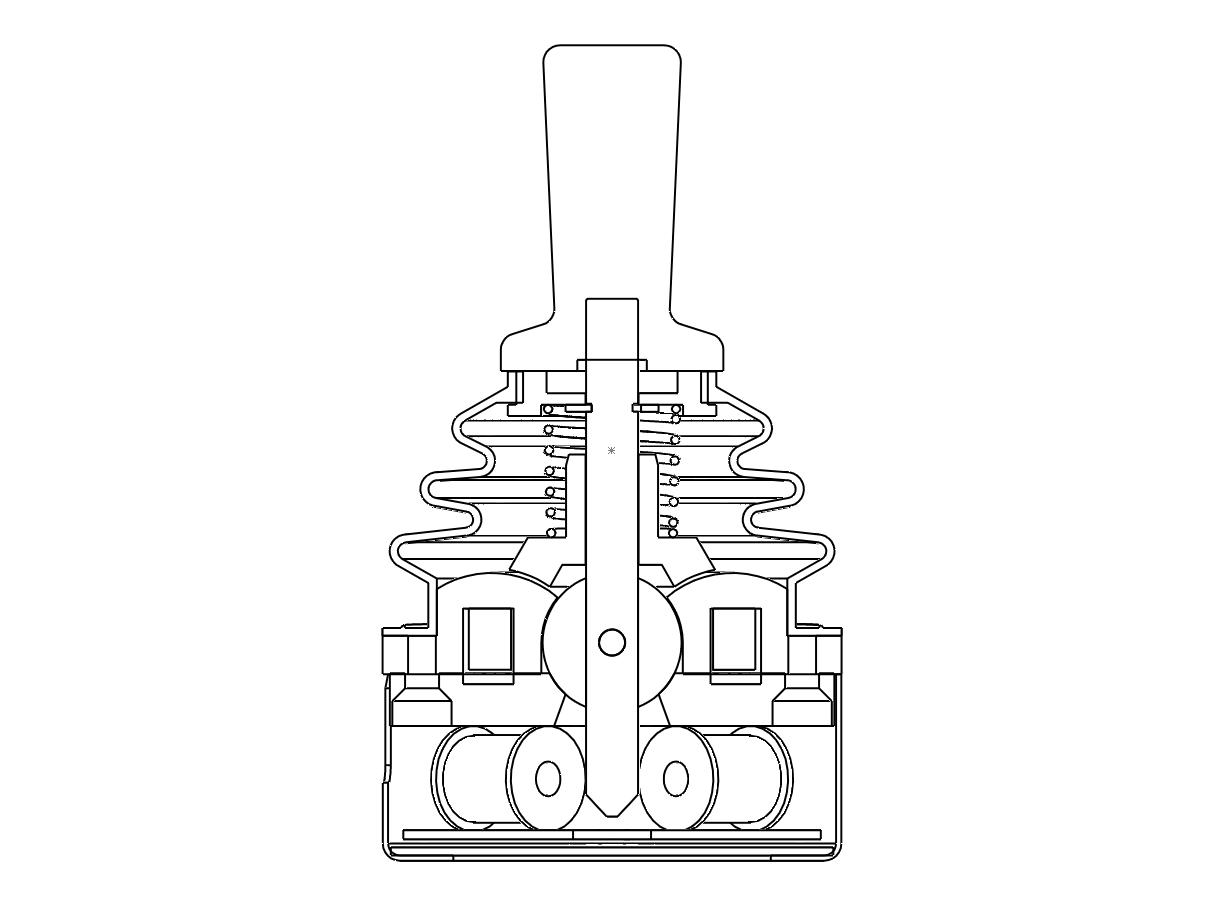

Potentiometer Joystick

The first joystick took advantage of component of Ohm's Law which in the field of electricity known as resistance, most engineers refer to this type of joystick as a potentiometer joystick. The potentiometer joystick has physical components that when moved allow either the increase or decrease of voltage or current through the variance of resistance within the electronic circuit. This variance of voltage or current is easily accomplished by the operator of the potentiometer joystick with only a very small amount of force applied. The potentiometer joystick technology opened the doors for electronic circuit control but it has limitations in terms of long term durability and reliability due to the wearing of moving parts and minor susceptibility to electromagnetic interference or radio frequency interference. Hall Effect Joystick

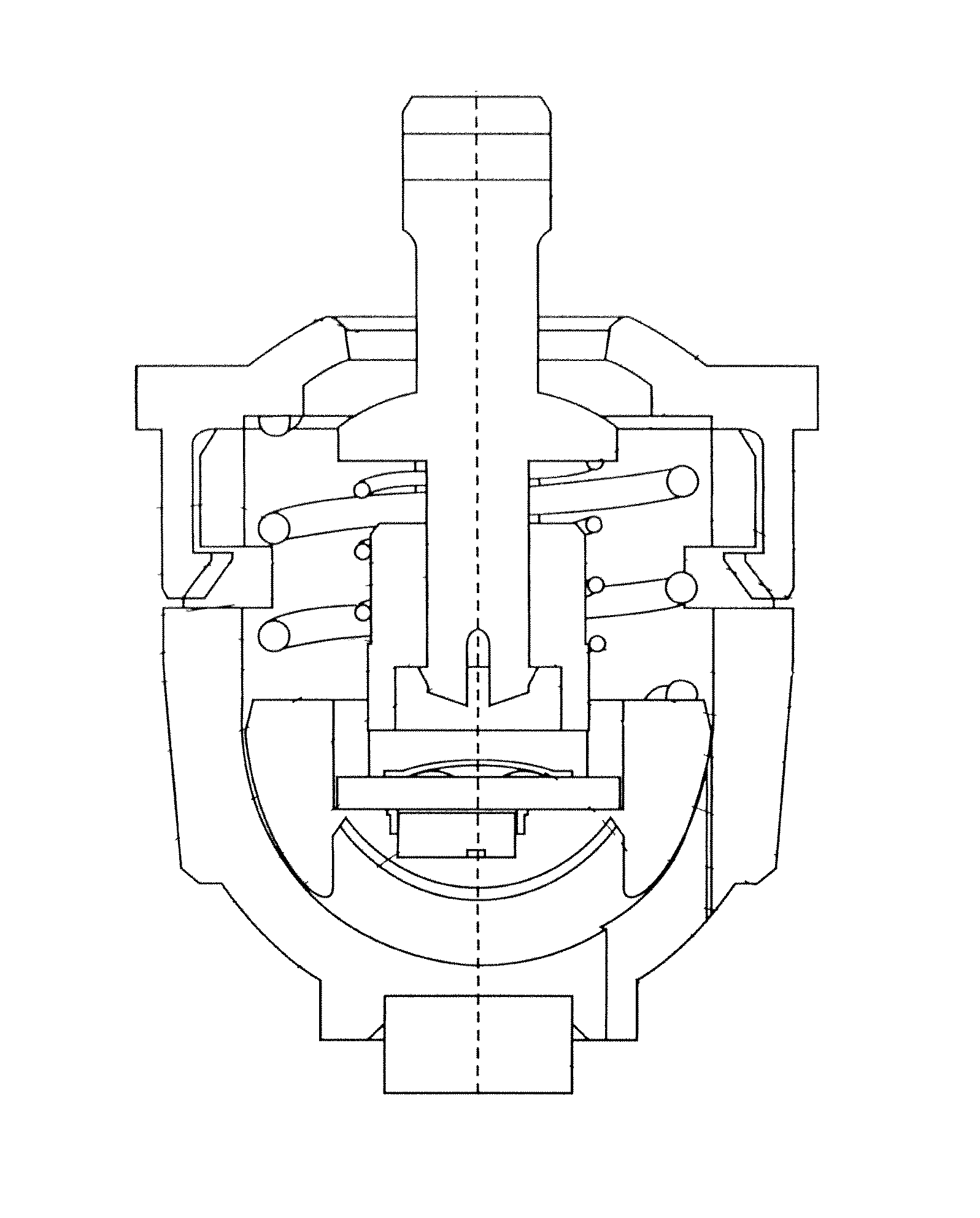

Hall Effect Joystick

Another technology, discovered by Edwin Herbert Hall applies the properties of electromagnetism through the usage of ferromagnetic material, gave rise to the hall effect joystick. The hall effect joystick has an advantage over the potentiometer joystick in that there is no physical contacting wear issue with the sensor itself. But the bails mechanism or gimbal mechanism for each magnet does move and will wear over time thus causing mechanical hysteresis. Also, the hall effect joystick does have a limitation in the very nature of the ferromagnetic material that is used, as it's magnetic field will change over time and is directly affected by temperatures (<0°C and >70°C). These variances in the magnetic field will cause the hall effect joystick to "drift". That is, the output voltage of the hall effect joystick will unwantedly vary and cause undesired effects. So the long term reliability of the hall effect joystick is limited.